-

STEP 1

Coconut selection and storage

We carefully select fresh, mature coconuts of the finest quality from local farmers and suppliers in South East Sulawesi.

-

STEP 2

Coconut De-shelling

Our skilled workers carefully remove the shell of the coconut, without breaking the coconut itself.

-

STEP 3

De-Paring

The testa (brown skin) of the coconut is carefully removed with the help of a de-paring/peeling knife. The coconut is then pierced to drain the coconut water which we store for production of Nata de Coco.

-

STEP 4

Inspection and Washing

The de-pared coconuts are thoroughly inspected to ensure only the best continue for further processing. They are then washed in sterile water.

-

STEP 5

Grinding

The de-pared coconuts are mechanically ground into flakes in a disk mill.

-

STEP 6

Steam Blanching

The coconut flakes are treated with steam in a screw conveyor to eliminate any pathogens and achieve sterility.

-

STEP 7

Drying

The wet coconut powder is dried gradually in an efficient hot air drier to bring the moisture to below 3%, while still retaining a bright, white color.

-

STEP 8

Cooling and Grading

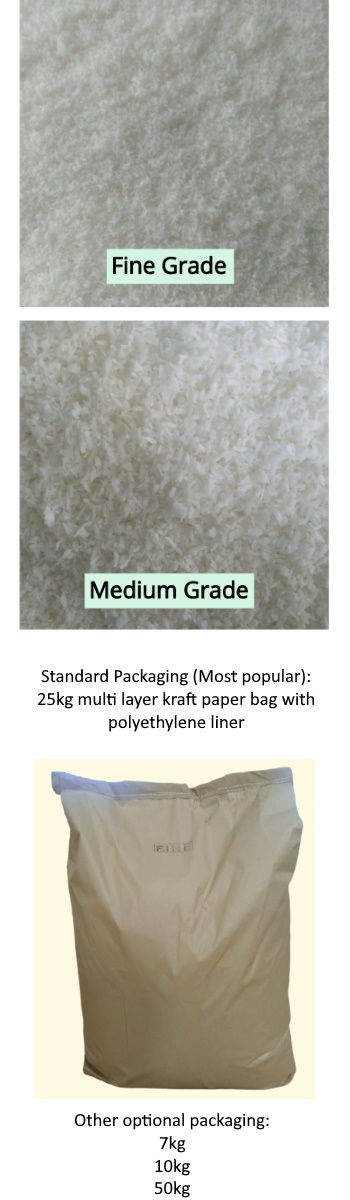

The dry coconut powder is cooled efficiently to bring the temperature down to ambient, to prevent cooking. Then it is graded to separate coarse, medium and fine sized particles.

-

STEP 9

Picking and Final Inspection

The graded product is inspected and any impurities are manually picked.

-

STEP 10

Metal Detection and Packaging

The final product is packed in multiply kraft paper bags with an inner plastic lining and then sent through a tunnel metal detector. The final bags are sent for storage in our warehouse.